- AI Software

- C3 AI Applications

- C3 AI Applications Overview

- C3 AI Anti-Money Laundering

- C3 AI Cash Management

- C3 AI CRM

- C3 AI Decision Advantage

- C3 AI Demand Forecasting

- C3 AI Energy Management

- C3 AI ESG

- C3 AI Intelligence Analysis

- C3 AI Inventory Optimization

- C3 AI Process Optimization

- C3 AI Production Schedule Optimization

- C3 AI Property Appraisal

- C3 AI Readiness

- C3 AI Reliability

- C3 AI Smart Lending

- C3 AI Sourcing Optimization

- C3 AI Supply Network Risk

- C3 AI Turnaround Optimization

- C3 AI Platform

- C3 Generative AI

- Get Started with a C3 AI Pilot

- Industries

- Customers

- Resources

- Generative AI

- Generative AI for Business

- C3 Generative AI: How Is It Unique?

- Reimagining the Enterprise with AI

- What To Consider When Using Generative AI

- Why Generative AI Is ‘Like the Internet Circa 1996’

- Can Generative AI’s Hallucination Problem be Overcome?

- Transforming Healthcare Operations with Generative AI

- Data Avalanche to Strategic Advantage: Generative AI in Supply Chains

- Supply Chains for a Dangerous World: ‘Flexible, Resilient, Powered by AI’

- LLMs Pose Major Security Risks, Serving As ‘Attack Vectors’

- C3 Generative AI: Getting the Most Out of Enterprise Data

- The Key to Generative AI Adoption: ‘Trusted, Reliable, Safe Answers’

- Generative AI in Healthcare: The Opportunity for Medical Device Manufacturers

- Generative AI in Healthcare: The End of Administrative Burdens for Workers

- Generative AI for the Department of Defense: The Power of Instant Insights

- What is Enterprise AI?

- Machine Learning

- Introduction

- What is Machine Learning?

- Tuning a Machine Learning Model

- Evaluating Model Performance

- Runtimes and Compute Requirements

- Selecting the Right AI/ML Problems

- Best Practices in Prototyping

- Best Practices in Ongoing Operations

- Building a Strong Team

- About the Author

- References

- Download eBook

- All Resources

- C3 AI Live

- Publications

- Customer Viewpoints

- Blog

- Glossary

- Developer Portal

- Generative AI

- News

- Company

- Contact Us

Implement AI-Powered Predictive Maintenance in Weeks

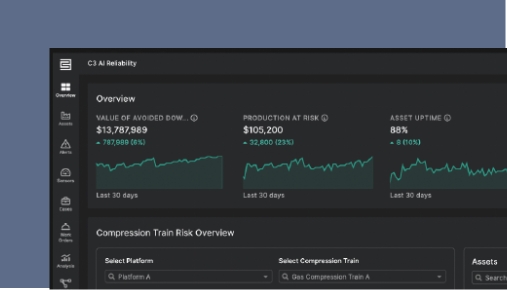

C3 AI Reliability

C3 AI Reliability is an AI-powered predictive maintenance application that enables enterprises to improve asset uptime and operational productivity. The application unifies operational data from multiple sources and applies advanced machine learning, natural language processing, and generative AI techniques to identify equipment risks in advance, provide digestible insight summaries, and generate recommended actions to help reduce downtime and maintenance costs.

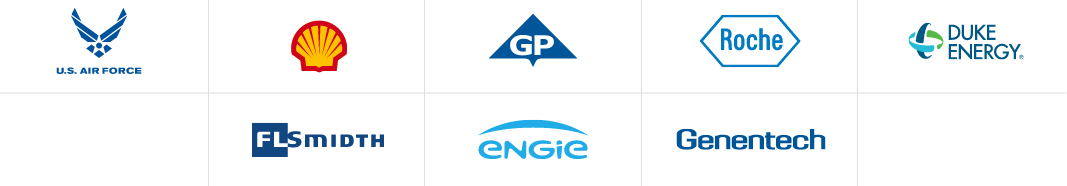

Customer Success Stories

Enterprise AI

at Georgia-Pacific

Working with C3 AI, Georgia-Pacific (GP) has emerged as an industry leader in the adoption of AI systems in the manufacturing industry.

Enterprise AI

at Shell

Shell has a rich history with digital technology and is committed to driving transformation at scale using enterprise AI.

Case Studies

Customer Viewpoints

Steve Bakalar

VP IT Digital Transformation

“I just think that in general, the culture and the aptitude and the passion that C3 personnel have is really by far some of the top we've ever experienced.”

Roshan Shah

VP, Collaboration & Support Center Operations

“I can buy all the parts, put them together, and try to build a computer, or I could go to an Apple Store and have a computer that works on day one. In more than one way, that's what we're seeing from your platform.”

Jim Hannan

EVP, CEO Enterprises

“There’s no question that C3 AI has capabilities we haven’t seen before, with something that gives us a platform to drive enterprise AI.”

Sriram Seshadri

Vice President and Head of Digital Smart Products

“But what we really like with C3 as a solution, it's not focusing on an application. It's focusing as a complete platform. They're very focused on value.”

Dan Jeavons

Vice President Computational Science and Digital Innovation

“I think it’s fair to say that digital technology is infusing every part of our business.”

Dan Brennan

VP - Business Operations

“We've got great expertise and advisory that comes in from C3.”

Dulce Borjas

VP and CIO, ENGIE North America

“ENGIE is looking to provide a zero-carbon future. The C3 AI Suite is important because it helps us build applications faster.”

Yves Le Gelard

CIO & Chief Digital Officer

"I have found a partner that's ready to listen, to be flexible, to adapt to what is a very large organization."

Varun Gowda

Head of Platform

“It really comes down to what C3 AI empowers ENGIE to do, which is harness and unlock the value from the data we collect on behalf of our customers.”

Insights

Take the Next Steps

Learn how our industry-leading Enterprise AI software products can help your organization.

Contact us at IR@C3.ai to learn more about investing at C3 AI.

For all other questions, please contact us here.